What Is 3D Printing?

At its core, 3d printing—also known as additive manufacturing—is the process of creating three-dimensional objects from digital designs by adding material layer by layer. Unlike traditional subtractive manufacturing methods that cut or carve material away, 3D printing builds objects from the ground up, minimizing waste and maximizing design flexibility.

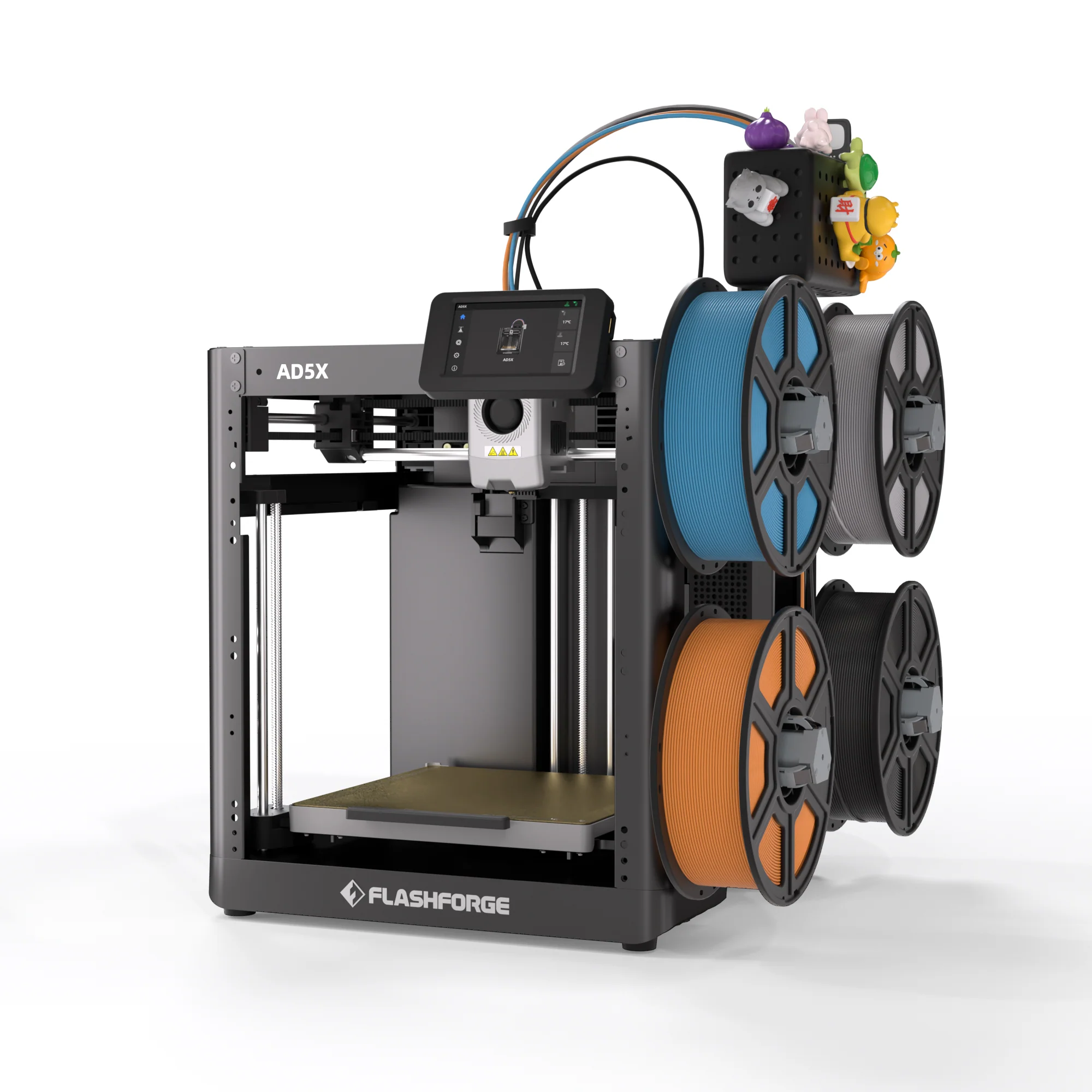

There are several common technologies used in 3D printing today. FDM (Fused Deposition Modeling) printers extrude melted filament to form objects, making them a popular choice for hobbyists and educators due to their affordability and versatility. Resin-based methods such as SLA (Stereolithography) and MSLA (Masked Stereolithography) use ultraviolet light to cure liquid resin, producing highly detailed, smooth models. More advanced technologies like SLS (Selective Laser Sintering) fuse powdered material into solid structures, enabling the production of durable, functional parts for industrial applications.

The Evolution of 3D Printing Technology

The journey of 3D printing began in the 1980s, when the first stereolithography printer was introduced. Over the decades, the technology evolved rapidly, moving beyond simple prototyping to functional production and even bioprinting. The introduction of desktop printers in the 2000s made the technology more affordable and accessible, sparking widespread adoption among makers and educators.

Today, 3D printing has become an essential tool in product development, allowing engineers to test ideas quickly and efficiently. The rise of advanced materials—from carbon fiber composites to biocompatible resins—has expanded the possibilities even further. In 2025, 3D printers are faster, more reliable, and capable of producing end-use parts with remarkable strength and accuracy.

Advantages of 3D Printing

The benefits of 3D printing extend far beyond convenience. One of its greatest strengths lies in design freedom. Complex geometries that are impossible or extremely costly to manufacture using traditional methods can be produced with ease. This has enabled industries to rethink product design and create parts that are lighter, stronger, and more efficient.

Another significant advantage is rapid prototyping. Designers can move from digital concept to physical model in a matter of hours, accelerating product development and reducing costs. This speed allows for iterative testing, leading to improved innovation and better end results.

Customization is also a defining feature of 3D printing. Unlike mass production methods, additive manufacturing allows for unique, one-off items tailored to individual needs. From patient-specific medical implants to personalized consumer products, the ability to create on-demand customized solutions is transforming industries.

Finally, sustainability is increasingly important in modern manufacturing. Because 3D printing is additive, it generates less material waste compared to traditional methods. The growing availability of eco-friendly and recyclable filaments further strengthens its role in sustainable production.

Applications of 3D Printing

The versatility of 3D printing makes it invaluable across diverse fields. In healthcare, doctors and researchers use it to produce prosthetics, dental models, surgical guides, and even bioprinted tissues for research. The aerospace and automotive industries rely on 3D printing to create lightweight, high-performance parts that reduce fuel consumption and enhance efficiency.

Education is another sector where 3D printing has made a profound impact. By integrating printers into classrooms, students gain hands-on experience with design, engineering, and problem-solving, preparing them for careers in science and technology.

For hobbyists and creators, 3D printing opens a world of creativity. Makers design and print everything from cosplay accessories to functional household items. Artists use it to experiment with sculptures, jewelry, and intricate models, blending technology with creativity.

Even unconventional sectors like fashion and food are adopting 3D printing. Designers experiment with wearable creations that push the boundaries of style, while chefs and researchers explore edible printing to produce customized meals.

Choosing the Right 3D Printer

With so many options available, selecting the right 3D printer depends on individual goals. Beginners may gravitate toward affordable FDM printers, which are reliable, easy to use, and capable of handling a wide range of projects. For applications requiring precision and detail, resin printers offer superior results, though they demand more careful handling and maintenance. Industrial users often rely on SLS or metal printers for durability and functionality in demanding applications.

When evaluating a printer, important considerations include build volume, print resolution, supported materials, and ease of use. Software compatibility and long-term reliability also play significant roles in determining whether a printer will meet user expectations.

The Future of 3D Printing

Looking ahead, the future of 3D printing is full of exciting possibilities. Bioprinting is advancing toward the creation of functional human tissues and, potentially, organs. Construction-scale printers are being used to build houses quickly and sustainably, addressing housing shortages worldwide. The integration of artificial intelligence into 3D printing software is also on the horizon, making printers more intuitive and efficient by automatically optimizing designs and settings.

As technology advances, costs continue to decline, making 3D printing more accessible to individuals and small businesses. The trend toward decentralization of manufacturing means that in the future, people may be able to print many of the products they need at home or in local maker hubs, reducing reliance on global supply chains.

Conclusion: Why 3D Printing Matters

The impact of 3D printing on modern society cannot be overstated. From accelerating product development to transforming healthcare and education, it is reshaping the way we design, manufacture, and create. Its combination of design freedom, rapid prototyping, customization, and sustainability makes it one of the most significant technologies of our time.

More Info: https://www.flashforge.com/